CHOOSE YOUR LANGUAGE

We will use the language of your country to serve you

- www.fkdmg.com

- www.fkdmg.com

Shenzhen

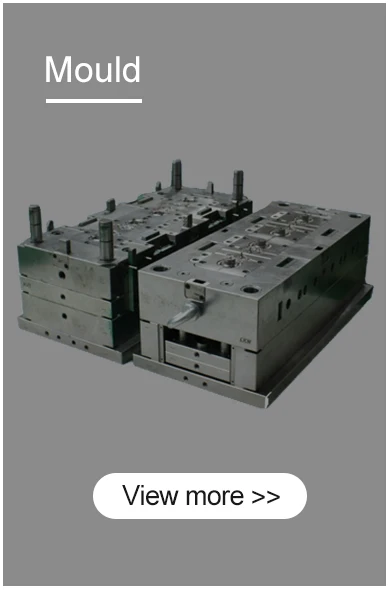

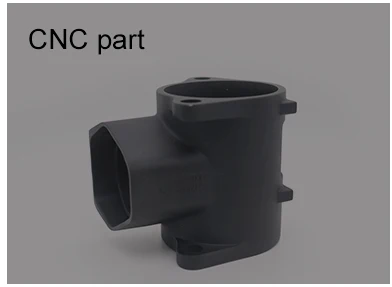

BSH Precision Die-Casting Products Co.,Ltd. is a specialized in all kinds of

metal die casting molds and all kinds of precision die-casting parts and CNC

precision parts.

The factory was established in 2006. Our company located in NO.121 Tangxiayong

industry , Songgang Town, Baoan district, Shenzhen, China.We are mold

designer,provide additional services ( CNC machining, polishing, deburring,

sanding, drilling, tapping and so on ) To meet our customer's

specifications. We also supply all kinds of surface treatment(painting,

anodizing, power coating ,sand blast, chrome plating etc.).Now the factory is

with 5000 square meter, company total assets is 15 million RMB ,and a staff of

nearly 150 members and workers, among which there are 12 engineers and over 50

senior technicians, who can make 3D designing and technical drawings with

CAD/CAM/CAE according to our customers' requirements , and use CNC Processing

Center, EDM center, 3-coordinate measurer, NC imitating milling machine, large

precision EDM, high-speed milling machines, spot machine, wiring machine and so

on.

The major production including automotive, Motorcycle accessories , bicycles,

electric cars accessories, electrical appliances, computer accessories,

industrial communication, lighting, motor bracket, electric equipment, security

accessories, monitor accessories, cooling equipment and other products of metal

die casting .And we are happy to co-operate with customer who need to do OEM

products by using aluminum/zinc alloy material.

Our key advantage over other is our attitude toward quality. We know what's

right, and not what just good enough. This is reflected in our quick response,

technical analyze of drawings, proactive approach in passing on our production

experience to help clients reduce cost and improve designs.

All in all, we aim to supply competitively priced quality products, with the

aim of creating a long lasting cooperation for mutual benefit.

We are strictly following the operation rules in the ISO9001:2008 Quality

System to constantly procure advanced testing and manufacturing equipment and

to develop all kinds of quality training, thus having effectively provided a

very strong guarantee for satisfying customer requirements.